Cleanroom Bags: What Are They and What Are They Used for?

April 22, 2021

Advantages and Applications of Nylon Cleanroom Packaging

June 11, 2021A Complete Guide to Cleanroom Poly Tubing and Its Use

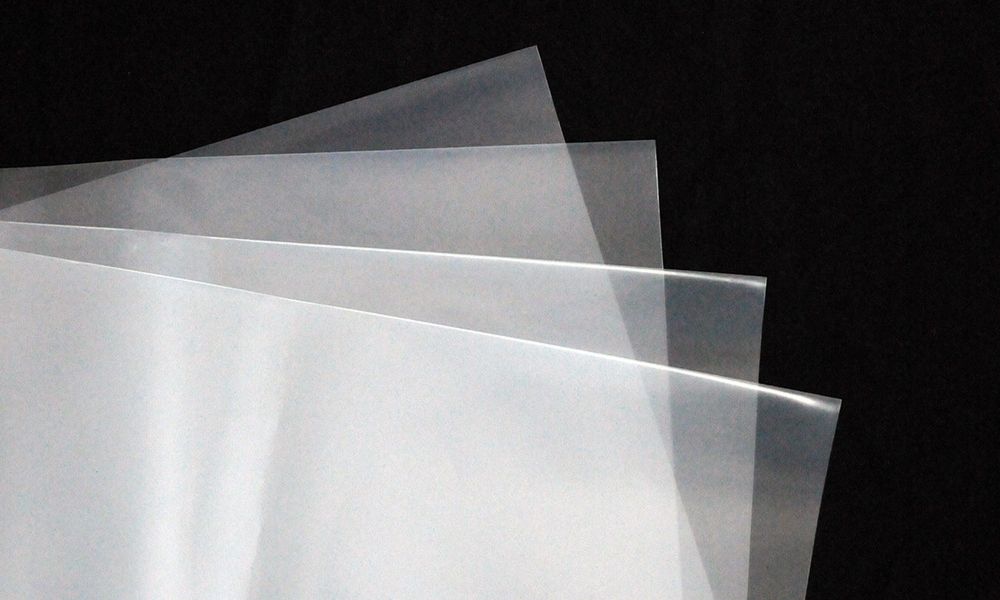

A simple yet versatile cleanroom poly tubing has a surprisingly broad range of applications. Its unique ability to stretch to the length of different items allows you to use it for safe packaging and shipping. Many industries use cleanroom tubing for their daily operations, especially medical, life sciences, automotive, and other fields.

Cleanroom poly tubing is made of 100% virgin low-density polyethylene, and it’s frequently sold in large rolls that look a lot like oversized Scotch tape. However, poly tubes are more convenient than typical tapes as they open at their mouth. That way, cleanroom staff can put objects lengthwise into the tubing, ensuring they’re fully encapsulated.

Poly tubing rolls are convenient for various purposes and items that require special care during shipment. They’re available in multiple lengths and widths, but reputable cleanroom packaging suppliers offer custom-tailored tubing of various dimensions, depending on your needs.

Pristine Clean Bags®: Customized Cleanroom Poly Tubing for Every Industry

Make your cleanroom operations safer and more convenient with Pristine Clean Bags® cleanroom tubing. We have a long-standing experience serving various industries with unique cleanroom packaging requirements, and you can count on us to provide custom-tailored cleanroom poly tubing or browse our stock to find something that meets your needs.

Our ISO-certified and FDA-approved cleanroom bags and tubing are manufactured according to the highest quality standards. Raw materials and virgin resins ensure 100% safe space for your sensitive objects, and you can choose specific dimensions that fit your products.

What is Cleanroom Poly Tubing?

Cleanroom poly tubing is made of low-density polyethylene that protects sensitive items from contamination and airborne particles. The base film consists of 100% virgin, barefoot resin free from anti-block additives commonly found in industrial polyethylene.

Cleanroom tubing is versatile, and industries use it for various applications that require placing the objects lengthwise. Once inside the roll, the product is fully encapsulated. Later, you can cut it from the rest of the roll, heat seal it, staple it, or tape it in place.

Poly tubing is highly beneficial due to its durability, strength, and ease of use. For that reason, most industries use it to protect their products and the overall manufacturing process from contaminants and other compromising substances.

Cleanroom Poly Tubes: Features & Benefits

Cleanroom poly tubing features a low-density polyethylene, which delivers substantial protection to items susceptible to damage from contamination and airborne particles. Pristine Clean Bags® offers high-quality cleanroom tubing made from virgin resins, non-animal origin, and surfactant-free materials. It is made in a certified cleanroom environment, which makes it suitable for ISO-class 5, 6, or 7 cleanrooms.

- FDA- and EU-approved cleanroom poly tubing

- ISO-classified

- The highest levels of traceability and documentation

- Global supply chain

- Pricing 20-30% below the US and EU markets

- Customized cleanroom tubing for different industries

The benefits of using our cleanroom poly tubing are endless, but we’ll highlight the most prominent ones:

- Safe equipment storage

- Biocompatible and stable

- Certified for a broad range of cleanroom applications

- High levels of cleanliness

- Microbial resistance

- Utmost reliability and efficiency

- Twisting and compression resistance

- Chemical compatibility

- Enhanced flexibility and transparency

- Suitable for different industries

What Industries Use Cleanroom Poly Tubing?

Cleanroom poly tubing provides the utmost protection from environmental factors, contaminants, and airborne particles. For that reason, it plays a vital role in different industries that produce sensitive equipment that could be damaged by even the smallest amount of contaminants inside the area.

Cleanroom Poly Tubing in the Medical Industry

Cleanroom poly tubing is incredibly useful in areas that require sanitary handling of sensitive materials, including the medical field. The medical industry uses cleanroom poly tubing for storing and shipping medical tools, including surgical instruments, lifesaving equipment, catheters, and other items used in hospitals and healthcare facilities. Poly tubing is also used in the pharmaceutical industry for packaging and shipping drugs and substances sensitive to contaminants and airborne particles.

Generally, cleanroom tubing is a staple in the following medical-related cleanrooms:

- Medical research cleanrooms: Industries use medical research cleanrooms to conduct medical experiments, research, and the development of new treatments and drugs.

- Medical device cleanrooms: Medical devices are all the tools used to diagnose, treat, or cure people. Since these areas require a 100% contaminant-free environment, their packaging must also be pristine. Cleanroom poly tubing is a preferred choice for medical devices and tools that must be packed lengthwise, and it must meet the ISO class requirements of the cleanroom in which they’re used.

- Pharmaceutical cleanrooms: Pharmaceutical products and equipment are manufactured inside the pharmaceutical cleanrooms, which often comply with ISO Class 5-7. Poly tubing for pharma cleanrooms protects products from humidity, contamination, and environmental factors that could affect their quality and functionality.

Ideally, cleanroom poly tubing for the medical and pharmaceutical industry should meet the following requirements:

- Contains known and traceable materials

- Doesn’t contain toxic or substances of very high concern (SVHC)

- Doesn’t have signs of tears, holes, cracks, or thinning

- Specifically designed for cleanroom applications

Cleanroom Poly Tubing in the Automotive Industry

Even the smallest amount of dust and other contaminants may be fatal in the automotive industry. As a result, the automotive parts may end up damaged, affecting the vehicle’s performance.

Automotive cleanrooms must maintain a specific level of cleanliness recommended for their particular purposes. That way, the company can prevent inconveniences caused by airborne particles and contaminants and deliver much safer and better-built vehicles in the long run.

Besides adequate air filtration system, HVAC unit, and proper static control, automotive cleanrooms must use appropriate cleanroom packaging supplies to store sensitive automotive parts, chips, and electronic components and protect them from external factors.

Anti-static cleanroom poly tubing offers substantial protection from electrostatic discharge, allowing you to pack long automotive parts safely and efficiently. ISO-certified tubing, bags, and films are essential for the automotive industry and all its subsectors, including:

- Automotive HVAC market – air conditioning, heating, and ventilation

- Automotive battery market

- Cockpit electronics market – navigation electronics market – navigation systems, sensors, passenger controls, etc.

- Automotive engine oil market.

Cleanroom Poly Tubing in the Life Science Industry

Life science cleanrooms are used for conducting scientific experiments, medical device testing, or drug production. The life science industry requires a safe and contaminant-free environment for these tasks to prevent potential life-threatening responses in patients resulting from chemical or microbial impurities inside a controlled environment.

Cleanroom bags are quintessential for maintaining controlled conditions inside a life sciences cleanroom. Low-density polyethylene (LDPE) bags are common for packaging tools and medical equipment, but poly tubing rolls have become a preferred option lately.

Life science cleanroom bags and poly tubing are used in different life science fields and subsectors, including:

- Biotech and biopharmaceutical fields

- Medical device and diagnostic products manufacturing

- Development of scientific equipment

- Life science and lab research

- Clinical testing and development

Cleanroom Poly Tubing in the Manufacturing Industry

The manufacturing industry has started implementing sophisticated technologies to deliver high-quality products and enhance its operations. Technologies like bio-engineering, 3D printing, and nanotechnology help build stellar products, but their components can be easily damaged by excessive levels of contaminants and airborne particles inside an area.

The manufacturing industry uses ISO-classified cleanrooms to build their products, ensuring that the air, temperature, pressure, and humidity are under control. The cleanroom equipment used for manufacturing purposes is also ISO-classified according to the cleanroom’s standards, ensuring the products leave the area safely.

Cleanroom poly tubing comes in handy for various applications in the manufacturing cleanroom, as it helps technicians store long items easily and conveniently. Besides, raw and barefoot resin ensures the utmost protection from bacteria, viruses, and particles that could affect the item’s quality and function.

ISO-classified and FDA-approved cleanroom poly tubing is widely utilized in manufacturing and its subsectors. Their versatility, convenience, and cleanroom-approved materials make them an ideal choice for the following fields:

- Electronic part manufacturing

- Biotechnology

- Life sciences

- Food manufacturing

- Automotive parts manufacturing

Cleanroom Poly Tubing for the Electronic Industry

Sensitive electronic components, including microchips, circuit boards, and microprocessors, can be damaged by excessive contamination levels or electrostatic discharge. While the staff is considered the biggest source of contamination, the facility where sensitive components are produced can also affect the product.

Suppose the electronic cleanroom doesn’t meet the requirements in terms of cleanliness and the allowed amount of particles. In that case, your products might not be able to maintain their optimal function and safety.

Depending on your cleanroom and product requirements, you can choose between anti-static and static shielding cleanroom bags. If classic bags don’t meet your needs, you can opt for anti-static poly tubing. The anti-static agents are added to minimize the buildup of static electricity, thus mitigating the risk of damage caused by electrostatic discharge.

Anti-static and static shielding cleanroom tubing is widely used by companies that manufacture electronic equipment, microchips, circuit boards, and other sensitive computer components. Generally, different types of electronic cleanroom bags are suitable for the following products and processes:

- Semiconductor supply and manufacturing services

- Industrial equipment

- Networking and communication tools

- Computer and office supplies

- Medical devices

- Electronics and home appliances

Cleanroom Poly Tubing in the Aerospace Industry

The aerospace industry conducts its daily tasks in highly controlled environments to ensure the product manufacturing process remains safe and intact. An aerospace cleanroom is where modern inventions arise, which calls for a pristine and contaminant-free environment and ISO-classified cleanroom equipment.

Cleanroom poly tubing is the most common choice for storing critical components of rockets, drones, airplanes, space crafts, gliders, and similar aerospace inventions that must be fully encapsulated and safe from contaminants.

Aerospace cleanroom bags and tubing are used for different purposes within the aerospace industry, including but not limited to:

- Spacecraft and satellite component manufacturing

- Engine component production

- Microchips and sensors

World-known companies like NASA, Boeing, SpaceX, Virgin Galactic, and others use aerospace poly tubing for their daily operations as they reduce the risks of device malfunctions or damages due to contamination exposure.

Once placed inside adequate cleanroom packaging, aircraft systems, drone electronic parts, and similar inventions are safe and ready for transportation and shipment.

Pristine Clean Bags®: Dependable Cleanroom Poly Tubing for Every Industry

Pristine poly tubing is manufactured in line with the latest environmental control packaging industry standards, delivering the utmost quality and performance that won’t disappoint you. Besides poly tubing rolls, we offer high-quality LDPE, HDPE, nylon, and moisture-barrier film, with or without easy tear formulation.

Thanks to our convenient global supply chain, we can support our customers’ facilities across the US and Europe. Besides fast delivery and stellar customer support, we offer special pricing that’s 20-30% below the US and European markets. For more information regarding our products and delivery, please call our customer support at (410) 581-0303.