Single Use Technology Guide

September 5, 2023

Cleanroom Sticky Mats Guide

January 17, 2025A Complete Cleanroom Wipes Guide

Learn About Wiper Materials, Edge Treatments, ISO Classes Applications, Proper Wiping Methods & Other Key Features

When it comes to maintaining cleanrooms, it is critical to use wipes that adhere to strict ISO requirements of your project and the wipes that you choose for cleaning must entirely fit your work’s demands. Cleanroom wipes are an important cleaning supply in keeping the cleanrooms free from contaminants like liquid, dust, human skin cells, leaks, lint, fibers, hair, and other particles.

In this guide, we will reveal how to pick the best wipes for cleaning controlled environments. We will explore different materials like polyester, micro denier, cotton, and nylon. You will learn about how different edging techniques may impact your work. You will also discover how to wipe properly and what the best handling and storage solutions are.

Pristine Clean Bags®: Top Quality ISO Class Compliant Clean Room Wipes

Pristine Clean Bags® is an ISO certified company with more than 4 decades of experience in cleanroom supplies and packaging. Our premium selection of cleanroom wipes collection includes 100% polyester cleanroom wipers, polyester SD cleanroom wipes microfiber (micro denier), and nonwoven cotton cellulose cleanroom wipes. Manufactured and processed to meet strict FDA and EU standards for controlled environments, our wipers are made from high-quality, low lint materials free of surfactants, and are intended for general cleaning of all types of surfaces, including furniture, electronic equipment, lab instruments, PCBs, high temperature process equipment, measuring tools, and many others. They are safe to use in cleanroom ISO Classes 3 and above, in industries like aerospace, pharmaceutics, electronics, biotechnology, research, medical device manufacturing, healthcare, and many others. For more information and technical questions, please fill out the form or contact us directly at (410) 581-0303.

What is Cleanroom Wiper

Cleanroom wipes are disposable cleaning supplies utilized for cleaning all kinds of surfaces within controlled environments. You can use them to wipe walls, tables, padded surfaces, equipment, machinery, fixtures, carts, and any other sensitive components. They are designed to effectively remove spills or residual material and maintain your work space particle and contaminant free and compliant with ISO requirements.

Cleanroom wipes can be dry, pre-wetted, sterile, or non-sterile, and are used in many industries, such as:

- Electronic part manufacturing

- Pharmaceuticals

- Biotechnology

- Life sciences

- Automotive industry

- Food manufacturing

- Research facilities

- Healthcare and hospital facilities

- Semiconductor industry

- Medical device manufacturing

How To Choose the Right Cleanroom Wipes?

In order to find suitable cleanroom wipers, you have to take into consideration several key factors and assess how they match your needs:

- Materials and their characteristics

- Size and weight

- ISO cleanroom classification compatibility

- Edge treatment

- Static dissipation (ESD requirements)

Overview of Different Materials

As essential cleaning tool in pharmaceuticals, university research, life science, biotechnology, nutraceuticals, vaccine industry, or high-tech semiconductor industries, materials used for making cleanroom wipes must be durable, strong, and maintain cleanroom’s ISO rating standards. Various materials are used to manufacture these wipers, each with unique characteristics that fit different projects’ needs. Common materials include:

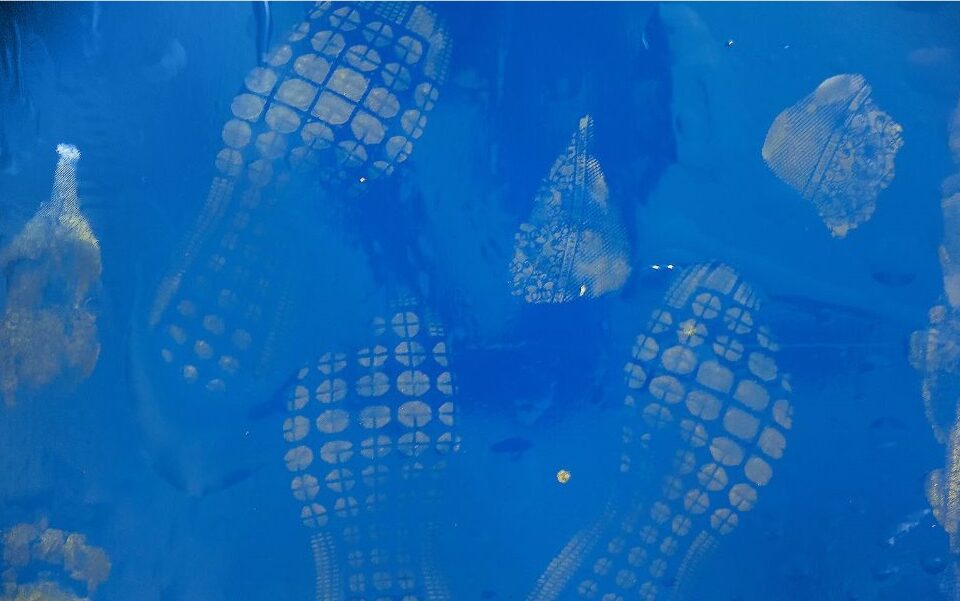

Polyester

Polyester is typically used for general purpose cleaning of electronics, optical devices, precision instruments, lenses, sensitive components. It is also used for polishing stainless steel in ISO Class 3 – 4+. The filaments can be stitched in several ways – single-knit, double-knit, double-layered or multi-layered, with tubular or laser cut and sealed edges. Polyester is lint free, very soft, fast-drying, resistant to abrasion and chemicals, and have good absorbency when combined with solvents.

Polyester/Cellulose blends (non-woven)

This lint-free material blend is popular choice for general cleaning and spill control in ISO Class 5 – 7+. Due to its excellent water absorbency properties it’s perfect for thick liquid or oil spill removal. Other features include strength, low levels of non-volatile residue, and chemical resistance. Another advantage is affordable price.

Micro denier

Also referred to as microfiber, this material is made of ultra-thin synthetic yarn, measuring less than 1 denier per filament (DPF) in thickness. Generally, micro denier wipers are made from polyester and nylon polymers and are utilized for cleansing, drying, applying and removing liquids, and cleaning nano-sized particles in ISO Classes 3 to 8. Although micro denier has impressive absorption abilities, it’s susceptible to tearing and breaking.

Polypropylene

Polypropylene is ideal for general cleaning, capsule cleaning, tray lining, equipment wiping, and spills in ISO 5 – ISO 8 Classes, especially in areas where solvents or acids are a concern. It can be used in microelectronics, food processing, defense, pharmaceutical, and biomedical controlled environments. Polypropylene is very soft, non-abrasive, resistant to chemical solvents and is usually pre-wetted with isopropyl alcohol solution. They are commonly food contact compliant with U.S. Food & Drug Administration Code of Federal Regulations Title 21 (FDA 21 CFR).

Nylon

Nylon knit material is suited for solution application, spill management, polishing magnetic media disk surfaces, and general cleaning duties in ISO Classes 4 – 8. Nylon is highly absorbent, durable, autoclave safe, with low levels of non-volatile residues.

Cotton

Cotton is strong and durable material of tight weave that is suitable even for high temperature use and autoclaves in ISO Classes 6 to 8. Due to durability, absorbency, thermal stability and excellent resistance to electrostatic discharge, cleanroom cotton wipers are ideal for managing water and solvent solutions, cleaning of enclosed injection molding, cleaning and polishing of magnetic media disks, cleaning equipment in high temperature areas.

Foam

In combination with IPA, wipers made of open-cell polyurethane foam are exploited for general maintenance of padded surfaces, solution application, and assembly operations in ISO 6 – 8 Classes. They represent a good replacement for sponges. Foam absorbs liquids well and provides low particle generation; however, it is not heat resistant.

Variations

Laundered polyester knit is great for scrubbing and applying liquid to various surfaces in cleanrooms ISO 5 – 8. It’s ideal for use in pharmaceuticals, micro-electronics, and semiconductor manufacturing. When polyester is laundered in ultra-filtered deionized water, it has extremely low fiber and particle shed and consistent quality.

Pre-wetted wipes come in many materials and solutions. They are designed to be used for disinfection within cleanrooms of ISO Class 5 and above. They are usually pre-saturated with isopropyl alcohol (IPA) and de-ionized water (DI water), saving technicians time on manually mixing and applying the correct amount of alcohol and water solvents. They can also be pre-wetted with Water for injection (WFI).

Edge Treatment

Another factor that can impact the level of contamination caused or spread, is edge treatment technique. If not properly finished, the edges can cause major contamination.

Continue reading to find out about how perimeters can be treated.

- Knife-cut edges – Edges are cut using sharp blade and may release fiber over time, as they are not sealed. They can be used in ISO 5 – 6 and higher, but it is not recommended to bring them into direct contact with final product due to possibility of contamination from released particles.

- Pressure heat sealing – This technique provides the cleanest possible flat edge without any stray fibers.

- Laser-cut and sealed edge – The edge is cut precisely and sealed using heat, leaving no residue.

- Ultrasonic sealing – This method outshines laser technique, as it creates softer and thinner edges with lower carbon levels.

- Wire-cut – This method of cutting and sealing costs less, but is not as neat as other techniques.

Cleanroom Classification

When considering which wipes to use for general maintenance tasks in your cleanroom, you have to take into account ISO Class compliance first. Below, you can see examples of which type of wipes to use for each classification level:

| Application | Cleanroom classification | Recommended material | Recommended edge treatment |

|---|---|---|---|

| Semiconductor, insulator | ISO Class 4 (Class 10) | Knitted polyester | Sealed edge |

| Aseptic Filling Area | ISO Class 5 (Class 100) | Knitted synthetics | Sealed edge |

| Prep area in Pharmaceuticals | ISO Class 6 (Class 1,000) | Polyester & cellulose blends | Cut edge |

| Medical manufacturing | ISO Class 7 (Class 10,000) | Cotton, foam, or composite materials | Cut edge |

Other Things to Consider When Buying Cleanroom Wipes

When looking for the right wipes for your controlled environment you should also take into consideration the following factors:

Size

- 4” X 4” – This is the most common size for cleaning sensitive surfaces, equipment, electronic devices, and water spills.

- 9″ X 9″ – This size is typically used for cleaning various surfaces and products as it fits the palm of the hand perfectly, when folded.

- 12″ X 12″ -Use larger size to wipe larger surfaces and large spills,or in combination with cleaning products.

Inherent Contamination

Be mindful of the fact that some types of materials can contain contaminants such as fibers, ions, and non-viable particles, which can impact the manufacturing process in controlled environments.

Water retention

Another important feature to think about is absorbency. For instance, to absorb wet pollutants, it is better to use cotton material than polyester, as polyester would only spread the contaminants around.

How To Fold Clean Room Wipes

When you fold the wipes in certain way, you will maximize their efficiency. They will be most effective for cleaning when you half-fold or quarter-fold them, and here’s how to do it:

- Remove wipes from the package

- Hold in mid-air (don’t place on any surface) and unfold the wiper completely

- Fold in half (and then in half again if you want a quarter-fold)

- You now have 4 sides for cleaning (2 inside and 2 outside). Each side will be used for one stroke of wiping.

- Remember to hold them mid-air the entire time and not place them on any surface

Cleanroom Wiping Guide

After you have chosen the right wipers, and after you have familiarized yourself with how to properly fold the wipes, it is time to learn about proper wiping rules and techniques:

- Do not wipe in circular options

- If needed, saturate with IPA or other solution

- For each stroke use clean wiper side

- Wipe in one direction only using parallel, overlapping strokes

- Always start from the cleanest area and wipe towards the less clean one

- Lift the wipe after each stroke

- Refold the wipe to expose unused sides

- After all four sides have been contaminated, refold and to expose the remaining 4 sides

- Dispose of wipes after you have used all 8 sides once

- Wipes pre-wetted with solvents should be disposed of in proper solvent cans

Storing Cleanroom Wipers

Proper storage of supplies is an essential part of controlling the cleanliness levels required for critical environments. To store wipes proper way, you must understand all the different types of packaging and how they must be handled in order not to contaminate the surroundings. This is why correct storage starts with the packaging.

Packaging

- Bag – Wipes intended for use in ISO 4-6 typically have dual bagging with poly liners. The outer bag should be sanitized before being brought into the cleanroom, while the wipers should remain in inner bags until it’s time to use them.

- Canister / Tub – Wipes packaged in canisters are usually pre-wetted with solutions which are compatible with controlled environments and their shelf life is typically prolonged.

- Box – In general, box packaging is not intended for direct transfer into the cleanroom, and it must be disinfected and decontaminated before being brought into the clean room.

Storage

Adequately storing your cleanroom wipers means to keep them away from contaminants like dust, moisture, or bacteria. Try to mimic controlled environment and keep them safe from contamination by storing them in one of the following ways:

- Cleanroom wipe dispensers – easy storage, easy access, and low risk of cross contamination.

- Controlled humidity chambers – These special chambers prevent electrostatic discharge by maintaining a stable humidity level. This keeps the wipes dry planned for use in settings sensitive to humidity or moisture.

- Shelving systems – There are several different kinds of shelving units available, each with its own set of benefits.

Stainless steel is durable, easy to clean and resistant to corrosion, making it suitable for storing cleanroom wipes.

Open wire shelving enables good air circulation and is lightweight. It is easily adjustable and use of stackable bins prevents cross-contamination.

Enclosed cabinets are another popular choice because they completely protects and prolongs the lifespan of the items stored inside from the outside factors. Smart cabinets enable tracking inventory.

Final Thoughts

As you can see, there are lots of different cleanroom wipes on the market, and to find the right one for your needs, you have to consider several important factors, like size, material, absorbency properties, or edge finishing. If you have technical questions, it is best to consult with the manufacturer directly so that you can be sure you have found the right match. For more information, feel free to speak to Pristine Clean Bags®, a global supplier of high-quality cleanroom wipes.